|

|

|

|

5면 생산 정밀도 보정 기능

5면에서 동일한 프로그램이 작동됩니다.

기계 공차 및 누적오류가 보정됩니다. |

|

|

|

|

|

|

|

|

|

3차원 생산 명령어 M206.

간단한 명령어로 3차원 좌표 회전을 수행할 수 있습니다.

이 기능은 모든 종류의 앵귤러 헤드에 유용하게 적용할 수 있습니

다. |

|

|

|

| |

|

|

|

|

간섭(충돌 방지)제어 기능

기계가공 전 간섭 확인 기능을 통해 기계 충돌을 방지할 수 있

습니다. |

|

|

|

| |

|

|

|

|

스핀들 하중 모니터링

2 단계 감지 방식으로 스핀들 및 공작물을 보호해 줍니다.

공구에 따라 감지 수준이 조정됩니다. |

|

|

|

| |

|

|

|

|

열 팽창 보정.

미리 설정된 스핀들 센서를 통해 열 변형을 억제할 수 있습니다.

장시간 머시닝 및 고정밀 머시닝에서도 만족한 결과를 얻을 수 있습니다. |

|

|

|

| |

|

|

|

|

| The spindle head and ram are made from a one piece casting for maximum rigidity. The spindle head and Z-axis transmission motor are designed on the same center line. To prevent thermal displacement and unparalleled torque, the spindle, motor and ball screw are property aligned on the same center line. |

|

|

|

| |

|

|

|

|

| Hartford-made true gear spindles provide more prominent power and reliability than ZF gearbox. Two spindle speed changes in high/low range provide ample power output in low speed range for heavy cutting loads, and high speed dor outstanding surface finish results. Forced circulation cooling and lubrication system is applied to spindle, bearings and gearbox to reduce thermal strain on the spindle and extend the service life. |

|

|

|

| |

|

|

|

|

| The table is self-finished on the machine for higher geometric accuracy. |

|

|

|

| |

|

|

|

|

- To improve on unstable signal for X-axis linear scale.

- To improve on unstable support problem caused by excessive spring deformation.

- To improve on bumping noise. |

|

|

|

| |

|

|

|

|

- Design Features : To improve self-defection of screw for upgrading positioning accuracy.

- Description : Applies a cam, allowing bearing to actuate a slide block combined with proper lubrication to ensure normal motion during a long time of poeration, By using the linear way calibrate vertical trabel accuracy, it ensures even upward supporting force. |

|

|

|

| |

|

|

|

|

| Y축 운동에 따라 좌우 유압 실린더의 압력이 변하여 균형을 잡아주므로 서보모터가 등분포하중에 더욱 잘 견딜 수 있고, 전류비 또한 개선됩니다. 이러한 개선은 W축 트랜즈미션 시스템의 안정성을 높이며 서보 제어 시스템의 유연성을 향상 시켜주어 결과적으로 머시닝 정밀도가 더욱 높아집니다. |

|

|

|

| |

|

|

|

|

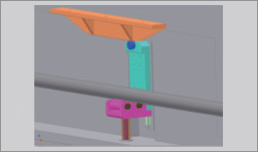

| 뒤쪽 면에 2개로 결합된 오른쪽 리니어 웨이 및 왼쪽 리니어 웨이에 Z축이 각각 부착되어 있습니다. Z축 리니어 웨이 상 3면에 단단하게 묶여 있어 Mb 및 Mc와 Ma 리니어 웨이에 압력이 고르게 분산되어 세 방향에서의 하중 용량이 최대가 됩니다. |

|

|

|

| |

|

|

|

|

(1) 열 제어 : 없음 vs 오일 냉각(하트포드)

(2) 열 상승 : 40도 vs 20도 |

|

|

|

| |

|

|

|

|

| 길이가 긴 볼 스크류는 자체의 무게 때문에 휠 수가 있으며 이는 닛트 레이디얼 하중에 실리는 원인이 됩니다. 볼 스크류 회전시 끝 부분에 휨응력이 야기되어 위치설정 정밀도가 불안정해지고 과도한 백리쉬가 발생할 수 있습니다. 이러한 모든 문제를 Y축 트랜즈시션 샤프트 지지대로 해결할 수 있습니다. |

|

|

|

| |

|

|

|

|

가상 모델 분석을 통하여 각 기계의 품질 목표를 달성할 수 있습니다.

FEA(Finite Element Analysis 유한 요소 분석)

기업은 유한 요소 분석을 통해 미리 제안된 설계를 확인할 수 있으며 제조나 건설에 앞서 고객이 요구한 세부사항을 실행할 수 있습니다.

EMA(Experiment Modal Analysis 실험 모델 분석)

전수 시간에 기초한 구조 측정을 통하여 몸체 구조(곡선 끼워맞춤)를 분석할 수 있으며 주요한 동적 파라미터(고유 진동수, 댐핑 비율, 모달 구조 등) 값을 얻을 수 있습니다.

MAC(Modal Assurance Criterion 모달 보증 기준)

FEA 가장 분석 데이터와 실험 모델 부석 데이터를 사용하여 MAC 직교를 실행할 수 있으며 FEA 데이터를 사용하여 기본 기계로 사용할 수 있습니다.

KGM(Kreuz Gitter Me β System 쿠르치 기터 미 베타 시스템)

간접 접촉 광학 스케일을 사용하여 최대오차를 정확하게 측정할 수 있으며 NC 파라미터를 사용하여 생산 정확도를 높일 수 있는 최적 파라미터 값을계산할 수 있습니다.

CSA(Cutting Spectrum Analysis 절삭 스펙트럼 분석)

절삭 스펙트럼 분석 및 실험

모달 분석을 통한 교차 확인 실행으로 밀링 채터링을 억제할 수 있습니다. |

|

|

|

| |

| |